- ISO 9001 Certified Organisation

- Contact us: (08) 9351 8051

Rubber Lining

Ceejay Engineering has been supporting rubber lining of all components and equipment used in a wide variety of industries including but not limited to mining, mineral processing, steel manufacturing and the water/wastewater industry. Our new facility in Kewdale primarily focuses on Cold Rubber Lining, with over 2000m2 of workshop space and 15 tonnes of lifting capacity.

Our Selection of Components & Services

• Pipes

• Sampling & Testing Machines

• Chutes

• Pulleys

• Storage Tanks

• Impeller Blades

• Cyclones

• Trommels

• Impeller Blades

• Cyclones

• Trommels

Top Reasons We Choose Rubber Lining

Corrosion Protection:

Rubber Lining can shield metal surfaces from corrosive substances, such as acids, alkalis & saltwater, preventing rust & degradation.

Abrasion Resistance:

Rubber lining can withstand abrasive materials and processes, making it ideal for protecting equipment in industries like mining and ore processing.

Chemical Resistance:

Rubber linings are designed to resist a wide range of chemicals and solvents, ensuring the integrity of equipment in chemical processing plants.

Temperature Resistance:

Depending on the type of rubber used, rubber linings can provide protection against extreme temperatures, both high and low.

Noise Reduction:

Rubber lining can also help dampen noise and vibration, making it useful in applications where noise control is important.

Applications

Rubber linings can be used for both abrasive and chemical applications on a variety of substrates including:

• Mild Steel

• Fiberglass

• Exotic Metals

• Aluminum

• Concrete

• Wood

• Stainless Steel

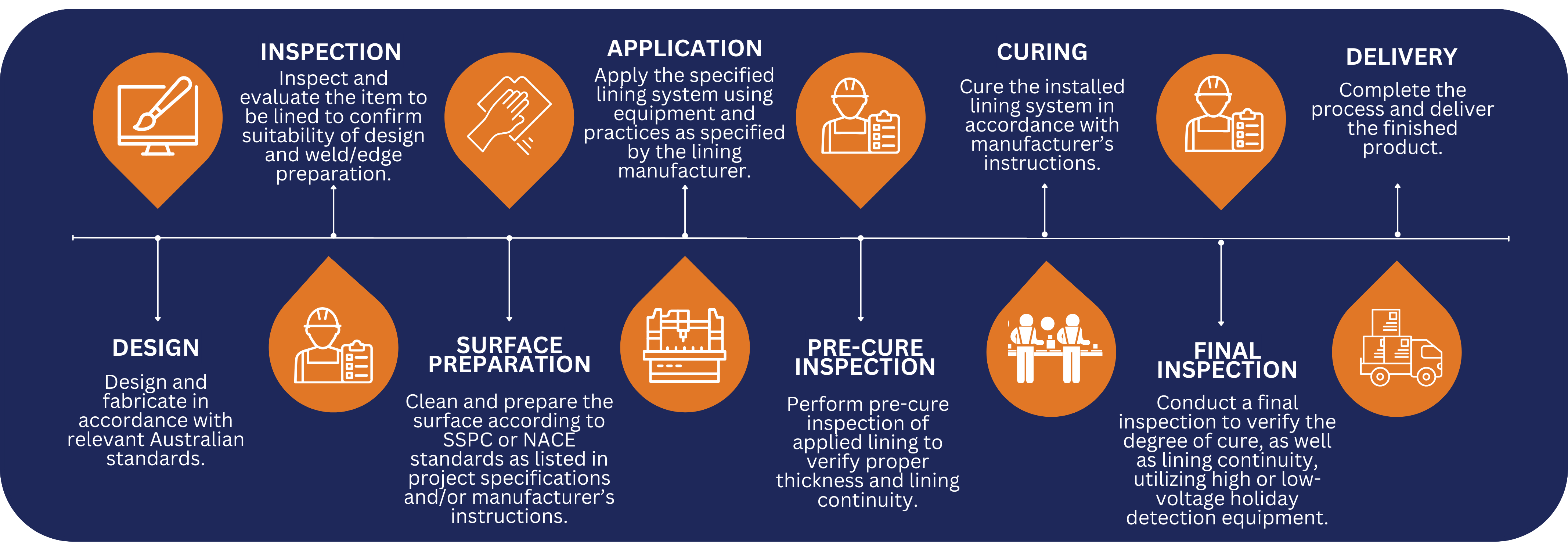

Our Rubber Lining Process

Quality Assurance

Being a market leader in manufacturing solutions for general and precision engineering means that we take our business seriously.

We maintain and follow the best possible processes, practices and workflows to deliver the highest level of client satisfaction as well as environmental and workplace safety.

ISO Certifications

We are ISO9001:2015, ISO1401:2015, ISO1801:2007 certified.

Quality testing

We conduct MPI, UT, NATA accredited tensile and chemical testing.

Material certifications

Charpy testing of materials and other tests as per customers requirements.